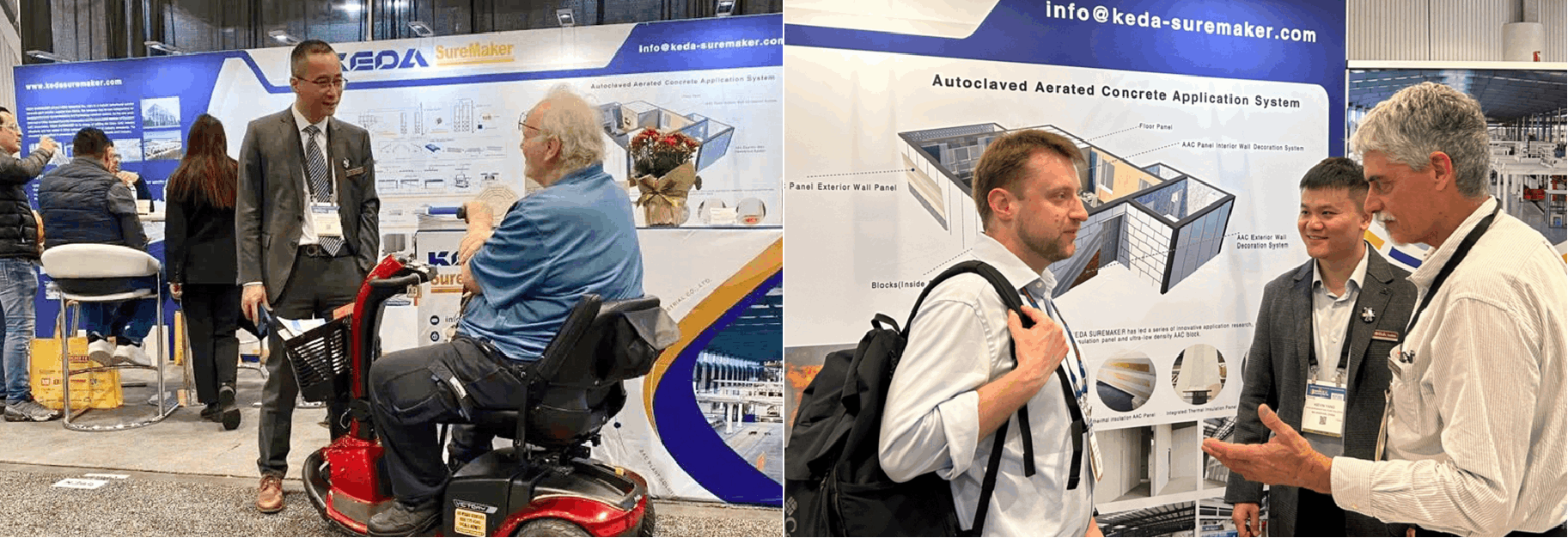

On January 23rd, Anhui KEDA Industrial Co., Ltd. showcased the KEDA SUREMAKER AAC Plant Solution at the World of Concrete (WOC) 2024 in the United States again, presenting to numerous manufacturers and buyers the company's solutions in AAC machinery manufacturing, production processes, and carbon emission management. This initiative aimed to offer green and sustainable development support for AAC industry customers worldwide in the context of carbon neutrality.

The year 2024 marks the 50th anniversary celebration of the World of Concrete (WOC) Expo in the United States. Organized annually by the Informa Group, this expo has evolved into a premier event for global exchange and trade in the concrete and construction machinery industries.

On the occasion of its 50th anniversary, professionals such as buyers and technical experts from around the world gather to provide a platform for the trade and exchange of concrete technology and building machinery from various countries. Additionally, the China Concrete and Cement Products Association (CCPA) sent a delegation to the expo for research and exchange purposes.

As one of the world's largest markets for construction and building materials, the United States, with its government's advocacy for suburbanization and the booming development of the real estate construction market, has provided powerful momentum for the demand for basic building materials.

Among these, the application of Autoclaved Aerated Concrete (AAC) is increasingly widespread, covering numerous scenarios such as residential areas, office buildings, and commercial constructions. In the residential sector, AAC materials have been widely used in the construction of self-built houses and apartment buildings.

With the continuous rise in demand for green and low-carbon building materials, AAC, known for its exceptional thermal insulation, fire resistance, and environmental attributes, has showcased significant growth potential within the American market. This feature aligns closely with the global push for green and low-carbon processes, positioning AAC materials for vast development prospects in the American market.

At this year's exhibition, Anhui KEDA Industrial Co., Ltd. not only showcased its holistic AAC plant solution, which has been validated through hundreds of successful projects worldwide, but also incorporated sustainability and digital innovation into its offerings. They are capable of providing AAC manufacturers with services such as energy-saving solutions, emission reduction strategies, carbon emission management, and production data traceability.

These services aim to guide AAC manufacturers towards sustainable development by adhering to green and low-carbon principles. The unique product technology and value proposition of Anhui KEDA Industrial Co., Ltd. attracted numerous exhibitors.

On the opening day of the exhibition, customers from around the world flocked to the booth for visits and negotiations. Mr. Chadwick CHEN, the Managing Director of Anhui KEDA Industrial Co., Ltd., emphasized, "KEDA SUREMAKER can provide global customers with comprehensive, full-lifecycle services ranging from raw material testing, planning and design, to machinery manufacturing, research and development, as well as engineering services and operational guidance. Our aim is to create efficient, environmentally friendly, and intelligent AAC green factories for our customers."

In recent years, Anhui KEDA Industrial Co., Ltd. has closely followed market demands, accelerating the pace of product upgrades.

Continuously striving for breakthroughs in areas such as intelligent control, production efficiency, and energy conservation and emission reduction, they have achieved Chinese leadership and international advancement in core technologies. Their products are now poised to penetrate the international high-end market.

Simultaneously, Anhui KEDA Industrial Co., Ltd. is advancing the globalization of the KEDA SUREMAKER brand through initiatives, including market expansion both within China and internationally, optimization of marketing strategies, and enhancements in quality services.

KEDA SUREMAKER | Green Intelligent Machinery for AAC:

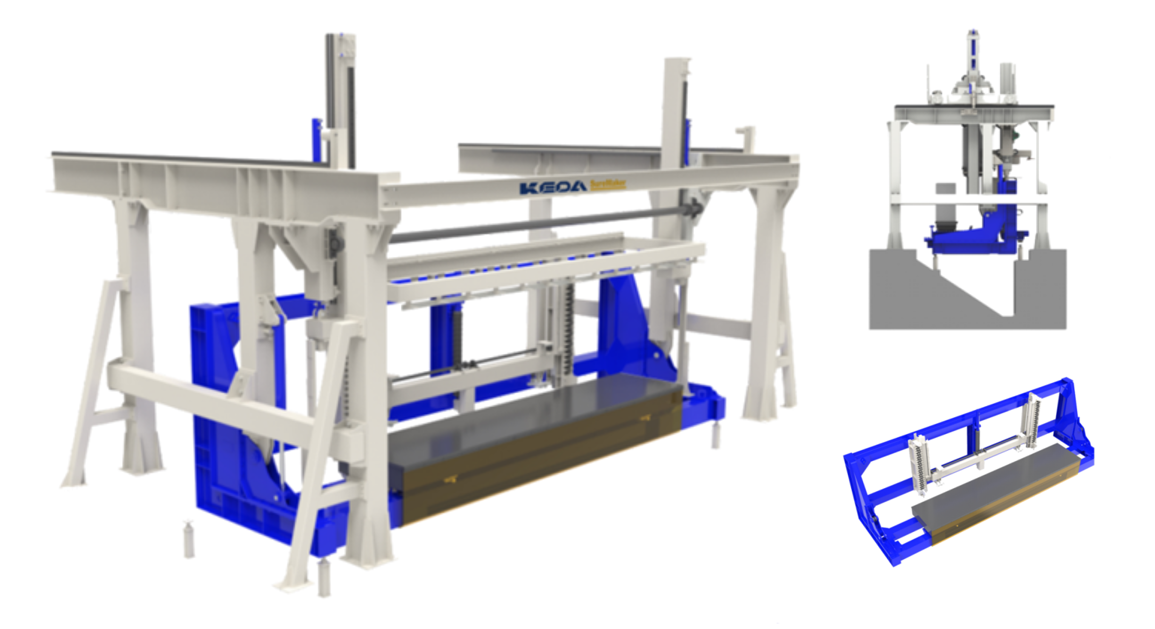

1. Air Suspension Tilting Machine

The tilting machine, a crucial component within the AAC production line, encounters various challenges including demanding production conditions, inadequate environmental hygiene, intricate civil engineering requirements, and maintenance difficulties, which have posed significant problems for numerous users.

In response to these challenges, Anhui KEDA Industrial Co., Ltd. has developed the air suspension tilting machine, effectively addressing key industry concerns. Its specific features are as follows:

Suspension Structure: The tilting machine features a suspended design, and utilizing hydraulic cylinders positioned overhead for minimal maintenance. This innovative approach not only reduces the complexity of constructing the tilting machine's foundation pit but also lowers civil construction costs.

Dual Workstation Structure: For high-capacity production lines, the small trolley setup waiting workstation is integrated to improve productionefficiency, enabling production cycles within 3 minutes.

Perforated Structure: The "L" frame of the tilting machine incorporates a perforated design, facilitating direct drainage of bottom slurry into the wastepit below. This prevents mechanicalmaterial buildup that could otherwise compromise the accuracy of bottom plate positioning.

Reasonable Rotation Center Design: The rotation center is positioned near the center of gravity, reducing the cylinder diameter and simplifying hydraulic power configuration, thus enhancing the reliability and durability of the tilting machine's mainframe.

Automatic Peeling Device Configuration: The peeling device incorporates a hydraulic lifting mechanism along with gear rack synchronous guiding, ensuring dependable operation and precise guiding accuracy.

Additionally, three sets of scrapers are integrated into the scraping device, with automatic compensation for the scraper used to scrape the autoclaved bottom plate. This ensures tight adhesion of the rubber surface to the side plate with consistent pressure, guaranteeing effective peeling.

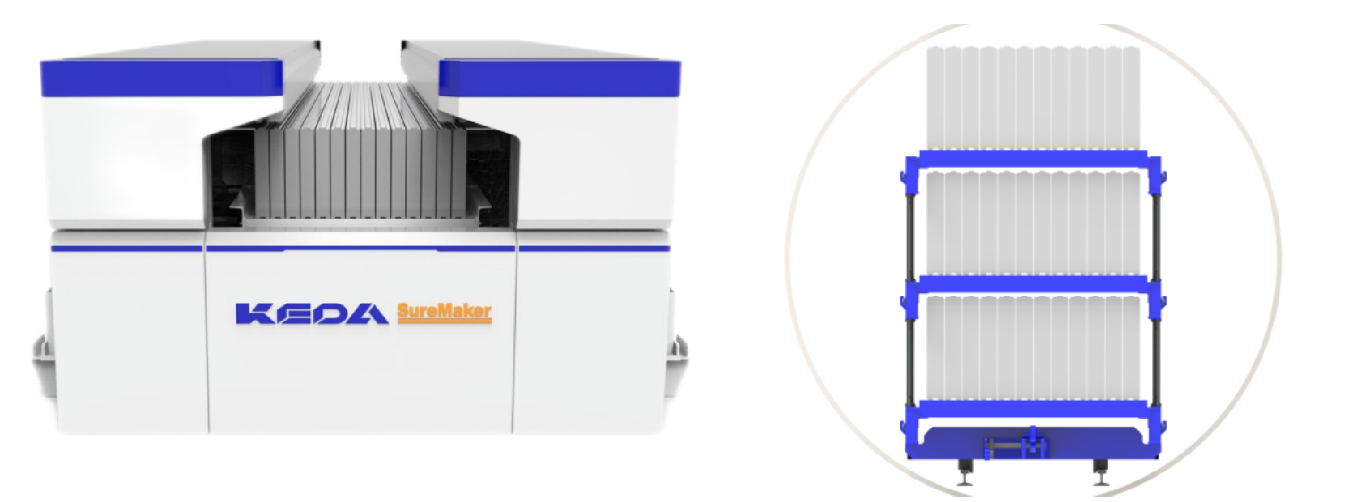

2. Green cake separating-flat cake autoclaving production process technology

As the prefabricated construction industry progresses, the demand for AAC panels is on the rise. In addressing this demand, Anhui KEDA Industrial Co., Ltd. has introduced the green cake separating-flat cake autoclaving production process technology with a focus on energy efficiency, shortened autoclaving times for panels, and reduced damage, aiming to support industry development. Here, the company delve into the main advantages and unique features of the core machinery, the green cake smart separating machine:

Main advantages of the green cake smart separating process relative to the white cake separating process are as follows:

The green cake smart separating process mainly creates gaps between the cake and the cake in the semi-finished products, enhancing the air permeability of the cakes during autoclaving, thereby shortening the autoclaving time of panels by approximately 1-2 hours or more.

The green cake smart separating process reduces the adhesion between the cake and the cake, eliminating the need for separating them after the finished products come out of the autoclaving, thereby avoiding the damage rate caused by high-strength separation of finished products.

In the green cake smart separating process, the autoclaved bottom plate adopts a hollow design, enhancing the air permeability during autoclaving.

The green cake smart separating process is more advantageous for the production of thin panels, offering higher efficiency and lower damage rates.

Main advantages of the green cake smart separating machine are as follows:

It employs dual-side separating to both sides and horizontal separating of two blocks simultaneously, ensuring high efficiency, with panels of 100 specifications processed within 3 minutes.

The lifting and separating actions of the green cake smart separating machine are driven by servo and screw transmission structures, ensuring the precision and synchronization of seam pulling.

The collets of the green cake smart separating machine can be adjusted in width according to different panel specifications, ensuring adaptability to various panel sizes.

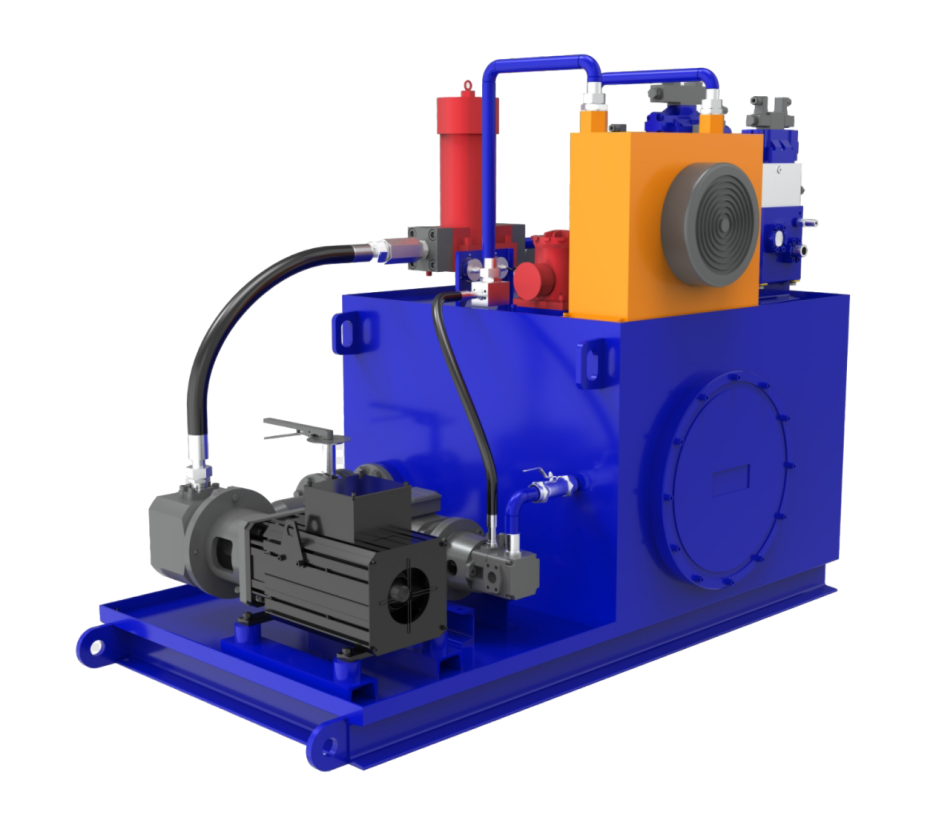

3. Servo Hydraulic System

In response to the Chinese carbon peaking and carbon neutrality policy initiative and to address inefficiencies in energy consumption, Anhui KEDA Industrial Co., Ltd. has conducted in-depth research into the energy consumption metrics of AAC production lines.

They have introduced the servo hydraulic system, which, following on-site testing and analysis, has been demonstrated to significantly reduce energy consumption, thereby cutting costs for user enterprises.

The servo hydraulic system boasts the following characteristics:

Low energy consumption: Servo motors exhibit higher energy utilization rates. For instance, in the case of a turnover demolding machine, the power consumption of the servo pump station is merely 40% of that of a conventional pump station.

Low oil temperature: The servo system adjusts pressure and flow based on actual needs, resulting in minimal heat generation loss, thereby keeping temperature rises generally within a 10°C range.

Fast Response and Acceleration: The servo system can swiftly switch between "small flow + high pressure" and "large flow + low pressure", enabling differential flow matching for both no-load and load conditions, thus facilitating rapid response.

The noise generated by the servo motor in the servo hydraulic system, combined with the internal gear pump, can be reduced by up to 30%.

Intelligent Panel Production Scheduling and Traceability System:

Intelligent manufacturing is the new direction of global manufacturing industry development. Developing intelligent manufacturing is the main direction of the Made in China 2025 strategy. In recent years, China has continuously introduced new policies to support the development of the intelligent machinery industry. As a traditional manufacturing industry, AAC production lines urgently need to enter the digital and intelligent ranks. Therefore, Anhui KEDA Industrial Co., Ltd. has introduced intelligent production scheduling systemand traceability system, detailed as follows:

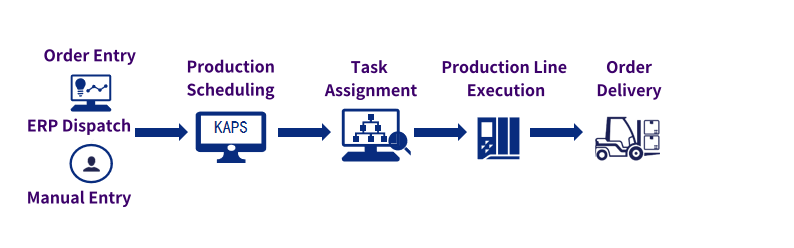

➤ Intelligent Panel Production Scheduling System

In the AAC panel production line, the panelrate of mould forming has consistently been a critical factor impacting production efficiency and capacity. Historically, manufacturers relied on manual mold allocation, which often failed to maximize the mold forming rate and led to material wastage due to inefficient allocation practices.

To remedy this issue, Anhui KEDA Industrial Co., Ltd. has developed an intelligent production scheduling system autonomously. Sales personnel can input orders via mobile apps, forms, and other channels. Once entered into the system, the scheduling software automatically identifies the optimal production schedule, prioritizing production orders with the highest mold forming rate, along with mesh or cage production orders.

Furthermore, it dynamically adjusts production orders based on real-time production conditions, thereby optimizing the rational allocation of production line capacity.

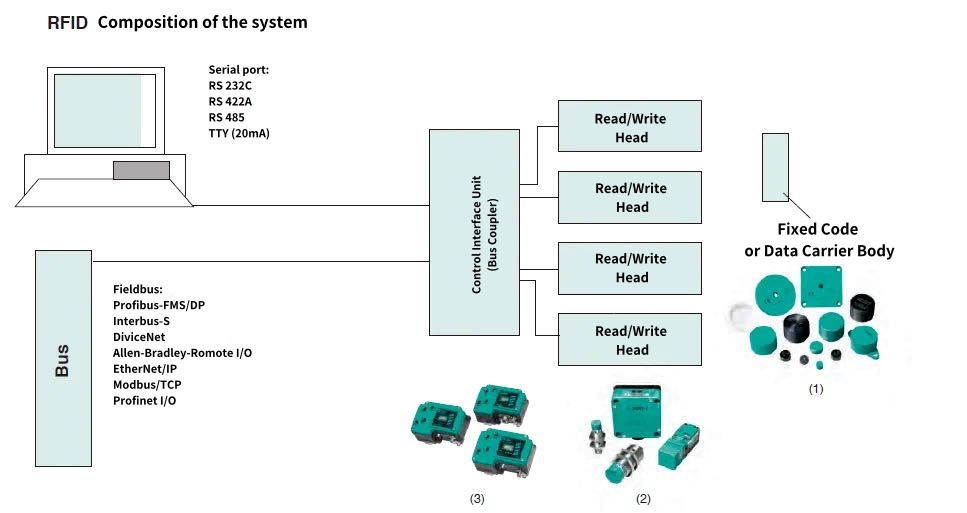

➤ Intelligent Traceability System

A smart traceability system has been developed to monitor products from the AAC production line, track the position of production line carriers in real-time, and record relevant production information data. This system seamlessly integrates with the information management system and provides intelligent guidance for production at the subsequent workstation.

By leveraging RFID chips and Anhui KEDA Industrial Co., Ltd.'s self-developed hardware tracking system, unique codes are assigned to mold carts, autoclaved carts, autoclaved bottom plates, scaffolds, and other carriers. The data from orders is recorded in various carriers along with background databases.

During the production process, this data is transformed, recorded, and utilized to form lifecycle management, thereby achieving intelligent management of the production line.

(KEDA SUREMAKER)